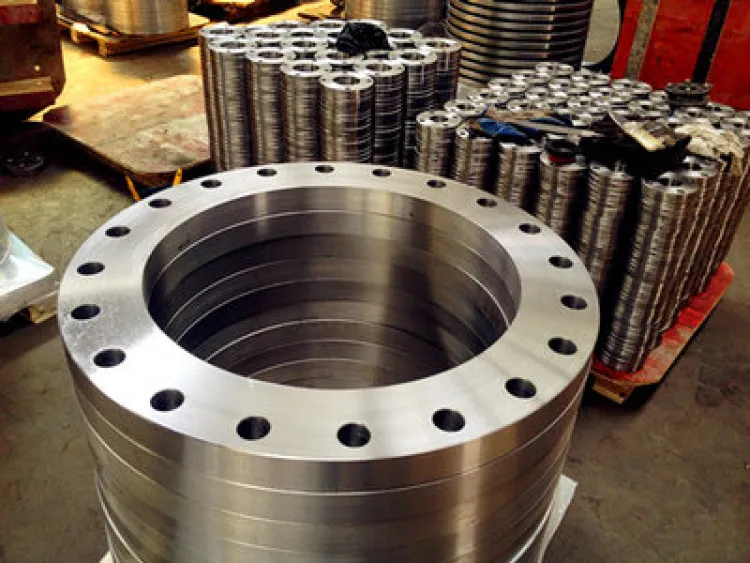

SS 316 / 316L Backing Ring Flange SS 316 and 316L backing ring flanges are used in piping systems to provide a secure and robust connection between pipes and other components. These flanges are manufactured from SS 316 and 316L stainless steel, which are both known for their excellent corrosion resistance, especially in environments exposed to chlorides and other harsh chemicals. The term "backing ring" refers to a ring-like flange used in conjunction with another flange to ensure a strong seal and proper alignment between the connected pipes. These backing rings can be used in various applications, including industries such as chemical processing, pharmaceuticals, oil & gas, and marine engineering. The main difference between 316 and 316L lies in their carbon content. 316L has a lower carbon content (≤0.03%) than 316, making it more resistant to sensitization and carbide precipitation during welding. This property makes 316L more suitable for high-welded environments. Uses of SS 316 / 316L Backing Ring Flange SS 316 / 316L backing ring flanges are highly versatile and find applications across various industries due to their durability, corrosion resistance, and ease of maintenance. Some of the most common uses include: 1. Chemical Processing: SS 316 and 316L are highly resistant to a wide range of chemicals, including acids, chlorides, and other corrosive substances. Backing rings made from these materials are used in chemical reactors, pipelines, and heat exchangers. 2. Marine Industry: Due to their high resistance to corrosion in seawater and chloride environments, 316 and 316L backing ring flanges are ideal for marine applications, including shipbuilding, offshore platforms, and underwater pipelines. 3. Pharmaceutical and Food Processing: Stainless steel 316 and 316L are often used in the pharmaceutical and food processing industries for their hygienic properties. Backing rings help in creating secure, clean connections in piping systems used for the transport of pharmaceuticals, food, and beverages. 4. Oil and Gas Industry: The corrosion resistance of SS 316 and 316L makes them ideal for harsh oil and gas environments, including deepwater drilling rigs and refineries. Backing ring flanges ensure a secure and leak-proof connection in critical pipelines. 5. Water Treatment: SS 316 / 316L backing ring flanges are used in water treatment plants, where the material’s resistance to corrosion from chlorides and other chemicals ensures long-term reliability. 6. Power Generation: In power plants, particularly in high-temperature and high-pressure environments, SS 316 / 316L flanges help connect pipes safely and efficiently, preventing leaks and ensuring system integrity. Composition of SS 316 / 316L The chemical composition of SS 316 and 316L is quite similar, but with a key difference in carbon content: SS 316 Composition: - Chromium (Cr): 16% – 18% - Nickel (Ni): 10% – 14% - Molybdenum (Mo): 2% – 3% - Carbon (C): 0.08% max - Manganese (Mn): 2% max - Silicon (Si): 1% max - Phosphorus (P): 0.045% max - Sulfur (S): 0.03% max SS 316L Composition: - Chromium (Cr): 16% – 18% - Nickel (Ni): 10% – 14% - Molybdenum (Mo): 2% – 3% - Carbon (C): ≤0.03% - Manganese (Mn): 2% max - Silicon (Si): 1% max - Phosphorus (P): 0.045% max - Sulfur (S): 0.03% max The primary difference between SS 316 and SS 316L is the lower carbon content of SS 316L, which gives it improved weldability and resistance to intergranular corrosion. Conclusion SS 316 / 316L backing ring flanges are critical components used in a wide variety of industries that demand high-performance, corrosion-resistant materials. Their superior resistance to chlorides, acids, and other corrosive environments makes them ideal for use in chemical, pharmaceutical, marine, oil & gas, and other industrial applications. The key difference between SS 316 and 316L lies in their carbon content, with 316L offering improved weldability and reduced susceptibility to intergranular corrosion. These backing ring flanges are designed to provide strong, leak-proof connections in critical systems where safety, reliability, and long-term performance are essential. Their versatility, combined with the material properties of SS 316 and 316L, ensures their continued use in high-demand applications. Whether for food processing, water treatment, or chemical processing, SS 316 / 316L backing ring flanges offer a durable and cost-effective solution for ensuring secure piping connections in harsh environments. If you have any requirements, please email us on sales@sagarsteel.net or call us on +91 9920177883

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

2024-12-12T15:16:49

SS 316 / 316L Backing Ring Flange SS 316 and 316L backing ring flanges are used in piping systems to provide a secure and robust connection between pipes and other components. These flanges are manufactured from SS 316 and 316L stainless steel, which are both known for their excellent corrosion resistance, especially in environments exposed to chlorides and other harsh chemicals. The term "backing ring" refers to a ring-like flange used in conjunction with another flange to ensure a strong seal and proper alignment between the connected pipes. These backing rings can be used in various applications, including industries such as chemical processing, pharmaceuticals, oil & gas, and marine engineering. The main difference between 316 and 316L lies in their carbon content. 316L has a lower carbon content (≤0.03%) than 316, making it more resistant to sensitization and carbide precipitation during welding. This property makes 316L more suitable for high-welded environments. Uses of SS 316 / 316L Backing Ring Flange SS 316 / 316L backing ring flanges are highly versatile and find applications across various industries due to their durability, corrosion resistance, and ease of maintenance. Some of the most common uses include: 1. Chemical Processing: SS 316 and 316L are highly resistant to a wide range of chemicals, including acids, chlorides, and other corrosive substances. Backing rings made from these materials are used in chemical reactors, pipelines, and heat exchangers. 2. Marine Industry: Due to their high resistance to corrosion in seawater and chloride environments, 316 and 316L backing ring flanges are ideal for marine applications, including shipbuilding, offshore platforms, and underwater pipelines. 3. Pharmaceutical and Food Processing: Stainless steel 316 and 316L are often used in the pharmaceutical and food processing industries for their hygienic properties. Backing rings help in creating secure, clean connections in piping systems used for the transport of pharmaceuticals, food, and beverages. 4. Oil and Gas Industry: The corrosion resistance of SS 316 and 316L makes them ideal for harsh oil and gas environments, including deepwater drilling rigs and refineries. Backing ring flanges ensure a secure and leak-proof connection in critical pipelines. 5. Water Treatment: SS 316 / 316L backing ring flanges are used in water treatment plants, where the material’s resistance to corrosion from chlorides and other chemicals ensures long-term reliability. 6. Power Generation: In power plants, particularly in high-temperature and high-pressure environments, SS 316 / 316L flanges help connect pipes safely and efficiently, preventing leaks and ensuring system integrity. Composition of SS 316 / 316L The chemical composition of SS 316 and 316L is quite similar, but with a key difference in carbon content: SS 316 Composition: - Chromium (Cr): 16% – 18% - Nickel (Ni): 10% – 14% - Molybdenum (Mo): 2% – 3% - Carbon (C): 0.08% max - Manganese (Mn): 2% max - Silicon (Si): 1% max - Phosphorus (P): 0.045% max - Sulfur (S): 0.03% max SS 316L Composition: - Chromium (Cr): 16% – 18% - Nickel (Ni): 10% – 14% - Molybdenum (Mo): 2% – 3% - Carbon (C): ≤0.03% - Manganese (Mn): 2% max - Silicon (Si): 1% max - Phosphorus (P): 0.045% max - Sulfur (S): 0.03% max The primary difference between SS 316 and SS 316L is the lower carbon content of SS 316L, which gives it improved weldability and resistance to intergranular corrosion. Conclusion SS 316 / 316L backing ring flanges are critical components used in a wide variety of industries that demand high-performance, corrosion-resistant materials. Their superior resistance to chlorides, acids, and other corrosive environments makes them ideal for use in chemical, pharmaceutical, marine, oil & gas, and other industrial applications. The key difference between SS 316 and 316L lies in their carbon content, with 316L offering improved weldability and reduced susceptibility to intergranular corrosion. These backing ring flanges are designed to provide strong, leak-proof connections in critical systems where safety, reliability, and long-term performance are essential. Their versatility, combined with the material properties of SS 316 and 316L, ensures their continued use in high-demand applications. Whether for food processing, water treatment, or chemical processing, SS 316 / 316L backing ring flanges offer a durable and cost-effective solution for ensuring secure piping connections in harsh environments. If you have any requirements, please email us on sales@sagarsteel.net or call us on +91 9920177883

2024-12-12T15:16:49

Keywords

- 91 9920177883

- 316 making

- ss 316

- 003 max

- ss 316l

- ss 316 316l

- chlorides acids

- critical components

- acids chlorides

- highly resistant

- ringlike flange

- harsh chemicals

- materials resistance

- 0045 max sulfur

- industries due

- highdemand applications

- industrial applications

- marine applications

- find applications

- costeffective solution

- 316l ensures

- material properties

- versatility combined

- longterm performance

- safety reliability

- critical systems

- intergranular corrosion

- reduced susceptibility

- wide variety

- improved weldability

- primary difference

- key difference

- leakproof connection

- harsh oil

- gas industry

- beverages 4 oil

- wide range

- highly versatile

- carbide precipitation

- 316l lies

- main difference

- marine engineering

- connected pipes

- proper alignment

- strong seal

- robust connection

- piping systems

- superior resistance

- corrosion resistance

- high resistance

- harsh environments

- gas environments

- chloride environments 316

- highwelded environments

- environments exposed

- chemical composition

- power plants

- pharmaceuticals food

- backing rings

- 316l makes

- carbon content

- durability corrosion resistance

- excellent corrosion resistance

- food processing industries

- carbon content 316l

- backing ring flanges

- property makes 316l

- corrosive environments makes

- connect pipes safely

- 316l stainless steel

- lower carbon content

- water treatment plants

- chemical reactors pipelines

- efficiently preventing leaks

- deepwater drilling rigs

- shipbuilding offshore platforms

Submit Your Enquiry