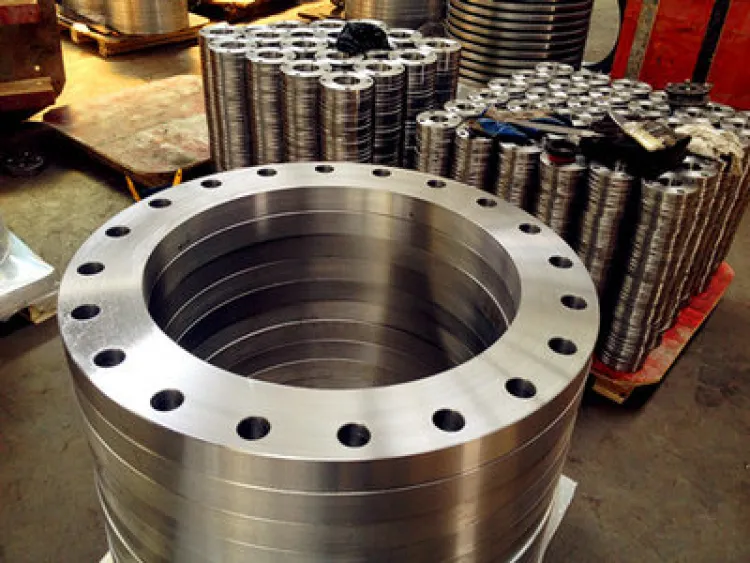

Stainless Steel Backing Rings In the vast world of industrial applications, where durability and reliability reign supreme, there exists a silent champion - the stainless steel backing ring. While it may not steal the spotlight like its flashier counterparts, its role in ensuring structural integrity and longevity is unparalleled. Picture this: a pipeline system, designed to withstand immense pressure and fluid dynamics, stretching across miles of terrain. Within this intricate network lies the humble backing ring, often overlooked yet indispensable. So, what exactly makes it worthy of our attention? First and foremost, stainless steel backing rings are the unsung guardians of joint integrity. Acting as a reinforcement mechanism, they provide crucial support to flange connections, preventing leaks and ensuring a tight seal. In environments where corrosion and erosion are constant threats, their robust construction offers a shield against the elements, maintaining the structural integrity of the system for years to come. But their significance goes beyond mere protection. These rings serve as facilitators of efficiency, streamlining installation processes and reducing maintenance efforts. With their precision engineering and compatibility with various piping materials, they offer versatility that is invaluable in diverse industrial settings. Moreover, stainless steel backing rings embody sustainability. Crafted from high-quality materials known for their longevity and recyclability, they contribute to reducing the carbon footprint of industrial operations. By promoting durability and minimizing the need for frequent replacements, they exemplify the ethos of responsible engineering. Yet, despite their numerous virtues, stainless steel backing rings often operate under the radar, overshadowed by more conspicuous components. It's time to shine a spotlight on these unsung heroes and acknowledge their indispensable role in the seamless functioning of our infrastructure. So, the next time you encounter a pipeline system or industrial setup, take a moment to appreciate the silent strength of the stainless steel backing ring. Behind every leak-free joint and sturdy connection lies its steadfast support, embodying resilience in the face of adversity. Stainless steel backing rings come in a variety of sizes and dimensions to accommodate the diverse needs of industrial applications. Here's a general overview of the typical sizes and dimensions you might encounter: Nominal Pipe Size (NPS): Stainless steel backing rings are often classified based on nominal pipe size, which refers to the approximate inner diameter of the pipe to which they are being attached. Common NPS sizes range from 1/2 inch to 48 inches or even larger, depending on the application requirements. Outer Diameter (OD): The outer diameter of the backing ring corresponds to the outer circumference of the flange or pipe it is designed to fit. This dimension is crucial for ensuring a proper fit and seal. OD sizes can vary widely based on the NPS and specific application needs. Inner Diameter (ID): The inner diameter of the backing ring is the opening through which the pipe passes. It should be slightly larger than the outer diameter of the pipe to allow for a snug fit without impeding flow. Like OD, ID sizes are contingent upon NPS and application specifications. Thickness: The thickness of stainless steel backing rings can vary depending on factors such as pressure rating and structural requirements. Common thicknesses range from a few millimeters to several inches, with thicker rings typically used for higher-pressure applications. Flange Standards: Backing rings are designed to conform to specific flange standards, such as ANSI (American National Standards Institute), ASME (American Society of Mechanical Engineers), or DIN (Deutsches Institut für Normung). These standards dictate dimensions such as bolt hole spacing, bolt hole diameter, and overall flange dimensions, which indirectly influence the size and dimensions of the backing ring. Material Grade: While not a dimension per se, the material grade of the stainless steel backing ring is critical for its performance and longevity. Common grades include 304, 316, and 316L stainless steel, each offering varying levels of corrosion resistance and mechanical properties. It's important to consult the specifications provided by manufacturers or industry standards to determine the precise sizes and dimensions needed for your specific application. Additionally, custom sizes and dimensions may be available upon request to accommodate unique requirements. COUNTRIES WE SERVED South America, Australia, Asia, USA, Russia, Africa, Europe, Singapore, Japan, Mauritius, Iran, Poland, Algeria, Zambia, Zimbabwe, Seychelles, Tunisia, Maldives, Sudan, Angola, DR Congo, Oman, UAE, Qatar, Kuwait, Saudi Arabia, Malaysia, Norway, Malawi, Cameroon, Sweden, Iraq, Israel, Portugal, Indonesia, Thailand, Sri Lanka,

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

2024-04-29T13:17:28

Stainless Steel Backing Rings In the vast world of industrial applications, where durability and reliability reign supreme, there exists a silent champion - the stainless steel backing ring. While it may not steal the spotlight like its flashier counterparts, its role in ensuring structural integrity and longevity is unparalleled. Picture this: a pipeline system, designed to withstand immense pressure and fluid dynamics, stretching across miles of terrain. Within this intricate network lies the humble backing ring, often overlooked yet indispensable. So, what exactly makes it worthy of our attention? First and foremost, stainless steel backing rings are the unsung guardians of joint integrity. Acting as a reinforcement mechanism, they provide crucial support to flange connections, preventing leaks and ensuring a tight seal. In environments where corrosion and erosion are constant threats, their robust construction offers a shield against the elements, maintaining the structural integrity of the system for years to come. But their significance goes beyond mere protection. These rings serve as facilitators of efficiency, streamlining installation processes and reducing maintenance efforts. With their precision engineering and compatibility with various piping materials, they offer versatility that is invaluable in diverse industrial settings. Moreover, stainless steel backing rings embody sustainability. Crafted from high-quality materials known for their longevity and recyclability, they contribute to reducing the carbon footprint of industrial operations. By promoting durability and minimizing the need for frequent replacements, they exemplify the ethos of responsible engineering. Yet, despite their numerous virtues, stainless steel backing rings often operate under the radar, overshadowed by more conspicuous components. It's time to shine a spotlight on these unsung heroes and acknowledge their indispensable role in the seamless functioning of our infrastructure. So, the next time you encounter a pipeline system or industrial setup, take a moment to appreciate the silent strength of the stainless steel backing ring. Behind every leak-free joint and sturdy connection lies its steadfast support, embodying resilience in the face of adversity. Stainless steel backing rings come in a variety of sizes and dimensions to accommodate the diverse needs of industrial applications. Here's a general overview of the typical sizes and dimensions you might encounter: Nominal Pipe Size (NPS): Stainless steel backing rings are often classified based on nominal pipe size, which refers to the approximate inner diameter of the pipe to which they are being attached. Common NPS sizes range from 1/2 inch to 48 inches or even larger, depending on the application requirements. Outer Diameter (OD): The outer diameter of the backing ring corresponds to the outer circumference of the flange or pipe it is designed to fit. This dimension is crucial for ensuring a proper fit and seal. OD sizes can vary widely based on the NPS and specific application needs. Inner Diameter (ID): The inner diameter of the backing ring is the opening through which the pipe passes. It should be slightly larger than the outer diameter of the pipe to allow for a snug fit without impeding flow. Like OD, ID sizes are contingent upon NPS and application specifications. Thickness: The thickness of stainless steel backing rings can vary depending on factors such as pressure rating and structural requirements. Common thicknesses range from a few millimeters to several inches, with thicker rings typically used for higher-pressure applications. Flange Standards: Backing rings are designed to conform to specific flange standards, such as ANSI (American National Standards Institute), ASME (American Society of Mechanical Engineers), or DIN (Deutsches Institut für Normung). These standards dictate dimensions such as bolt hole spacing, bolt hole diameter, and overall flange dimensions, which indirectly influence the size and dimensions of the backing ring. Material Grade: While not a dimension per se, the material grade of the stainless steel backing ring is critical for its performance and longevity. Common grades include 304, 316, and 316L stainless steel, each offering varying levels of corrosion resistance and mechanical properties. It's important to consult the specifications provided by manufacturers or industry standards to determine the precise sizes and dimensions needed for your specific application. Additionally, custom sizes and dimensions may be available upon request to accommodate unique requirements. COUNTRIES WE SERVED South America, Australia, Asia, USA, Russia, Africa, Europe, Singapore, Japan, Mauritius, Iran, Poland, Algeria, Zambia, Zimbabwe, Seychelles, Tunisia, Maldives, Sudan, Angola, DR Congo, Oman, UAE, Qatar, Kuwait, Saudi Arabia, Malaysia, Norway, Malawi, Cameroon, Sweden, Iraq, Israel, Portugal, Indonesia, Thailand, Sri Lanka,

2024-04-29T13:17:28

Keywords

- DIN

- UAE

- Asia

- time

- face

- flow

- ANSI

- ASME

- Oman

- Iran

- Iraq

- Qatar

- years

- ethos

- radar

- Japan

- leaks

- Sudan

- miles

- Sweden

- Malawi

- Israel

- moment

- Kuwait

- Russia

- Europe

- Angola

- Poland

- Norway

- Zambia

- Africa

- shield

- opening

- variety

- terrain

- Tunisia

- Normung

- request

- erosion

- Algeria

- factors

- DR Congo

- OD sizes

- Thailand

- ID sizes

- snug fit

- Zimbabwe

- Maldives

- Malaysia

- Cameroon

- Portugal

- elements

- 1/2 inch

- 304, 316

- Australia

- Singapore

- Mauritius

- Sri Lanka

- spotlight

- longevity

- COUNTRIES

- attention

- 48 inches

- adversity

- Indonesia

- Seychelles

- vast world

- durability

- resilience

- proper fit

- efficiency

- tight seal

- millimeters

- connections

- versatility

- performance

- reliability

- Saudi Arabia

- custom sizes

- environments

- significance

- facilitators

- compatibility

- manufacturers

- unsung heroes

- recyclability

- South America

- precise sizes

- Common grades

- diverse needs

- thicker rings

- typical sizes

- Outer Diameter

- varying levels

- Material Grade

- infrastructure

- fluid dynamics

- several inches

- sustainability

- joint integrity

- mere protection

- silent champion

- pipeline system

- silent strength

- pressure rating

- leak-free joint

- crucial support

- industrial setup

- American Society

- unsung guardians

- Common NPS sizes

- immense pressure

- general overview

- carbon footprint

- constant threats

- numerous virtues

- bolt hole spacing

- steadfast support

- intricate network

- Nominal Pipe Size

- sturdy connection

- Common thicknesses

- indispensable role

- industry standards

- Deutsches Institut

- bolt hole diameter

- maintenance efforts

- unique requirements

- robust construction

- humble backing ring

- outer circumference

- Mechanical Engineers

- seamless functioning

- corrosion resistance

- structural integrity

- 316L stainless steel

- industrial operations

- frequent replacements

- flashier counterparts

- precision engineering

- mechanical properties

- conspicuous components

- high-quality materials

- installation processes

- reinforcement mechanism

- structural requirements

- industrial applications

- responsible engineering

- various piping materials

- application requirements

- specific flange standards

- overall flange dimensions

- specific application needs

- approximate inner diameter

- application specifications

- diverse industrial settings

- higher-pressure applications

- Stainless Steel Backing Rings

- American National Standards Institute

Submit Your Enquiry