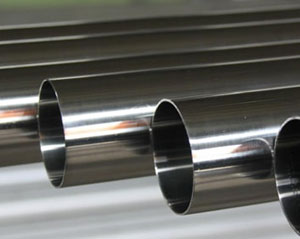

ASTM A554 304/304L ERW Pipes Introduction: ASTM A554 304/304L ERW pipes refer to Electric Resistance Welded stainless steel pipes that conform to the ASTM A554 standard, specifically made from the 304 and 304L grades of stainless steel. These pipes are produced through an electric resistance welding process, which involves the heating and joining of metal edges through an electric current. They are characterized by excellent corrosion resistance, strength, and formability. 304 and 304L are two of the most commonly used grades in the stainless steel family, and they are often selected for applications requiring a good combination of strength, corrosion resistance, and weldability. ASTM A554 304/304L ERW pipes are used in a variety of industries and applications due to their durability, corrosion resistance, and excellent formability. Common uses include: Construction and Architecture: Used for structural elements, handrails, and ornamental design elements due to their aesthetic appeal and strength. Food and Beverage Processing: Stainless steel's resistance to corrosion and staining makes it ideal for use in equipment like pipes, tanks, and valves in food processing and beverage lines. Pharmaceutical and Medical Applications: The corrosion resistance and ease of sterilization make these pipes suitable for use in medical equipment, surgical instruments, and pharmaceutical manufacturing. Automotive: In the automotive industry, 304/304L ERW pipes are used for exhaust systems, fuel lines, and other parts that require resistance to heat and corrosion. Chemical Processing: Their ability to resist a wide variety of chemicals makes them suitable for chemical processing equipment, reactors, and heat exchangers. HVAC Systems: Due to their strength and resistance to oxidation, they are used in heating, ventilation, and air conditioning (HVAC) systems. Marine and Offshore Applications: The pipes are used in marine environments due to their high resistance to seawater corrosion. Composition: The composition of 304 and 304L stainless steel, which are used to produce ASTM A554 ERW pipes, is as follows: 304 Stainless Steel (Typical Composition): Chromium (Cr): 18.0% - 20.0% Nickel (Ni): 8.0% - 10.5% Manganese (Mn): 2.0% max Silicon (Si): 1.0% max Carbon (C): 0.08% max Phosphorus (P): 0.045% max Sulfur (S): 0.03% max Iron (Fe): Balance 304L Stainless Steel (Typical Composition): Chromium (Cr): 18.0% - 20.0% Nickel (Ni): 8.0% - 12.0% Manganese (Mn): 2.0% max Silicon (Si): 1.0% max Carbon (C): 0.03% max (lower than 304) Phosphorus (P): 0.045% max Sulfur (S): 0.03% max Iron (Fe): Balance Key Properties: Corrosion Resistance: Both 304 and 304L offer excellent resistance to rust, corrosion, and staining in most environments, especially in food, medical, and marine applications. Weldability: 304L has a lower carbon content, which enhances its weldability and reduces the likelihood of carbide precipitation during welding. Strength: Both grades offer good tensile strength and resistance to high temperatures. Formability: 304 and 304L are highly formable and easy to manipulate into various shapes, which is useful in applications like handrails, tubes, and pipes. Conclusion: ASTM A554 304/304L ERW pipes are a high-quality choice for various industries requiring a combination of strength, corrosion resistance, and ease of fabrication. These pipes are durable, easy to weld and form, and maintain excellent performance even in harsh environments. With the corrosion resistance and aesthetic appeal of stainless steel, these pipes are invaluable in industries such as food processing, pharmaceuticals, automotive, and architecture. The key advantage of 304L over 304 is its improved weldability and reduced risk of corrosion in welded areas, making it the preferred choice in applications involving extensive welding. Overall, ASTM A554 304/304L ERW pipes offer reliable performance, longevity, and versatility, making them an excellent material choice across a broad range of applications. If you have any requirement - please email us on sales@sagarsteel.net or call us on +91 9920177883

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

2025-02-13T11:38:11

ASTM A554 304/304L ERW Pipes Introduction: ASTM A554 304/304L ERW pipes refer to Electric Resistance Welded stainless steel pipes that conform to the ASTM A554 standard, specifically made from the 304 and 304L grades of stainless steel. These pipes are produced through an electric resistance welding process, which involves the heating and joining of metal edges through an electric current. They are characterized by excellent corrosion resistance, strength, and formability. 304 and 304L are two of the most commonly used grades in the stainless steel family, and they are often selected for applications requiring a good combination of strength, corrosion resistance, and weldability. ASTM A554 304/304L ERW pipes are used in a variety of industries and applications due to their durability, corrosion resistance, and excellent formability. Common uses include: Construction and Architecture: Used for structural elements, handrails, and ornamental design elements due to their aesthetic appeal and strength. Food and Beverage Processing: Stainless steel's resistance to corrosion and staining makes it ideal for use in equipment like pipes, tanks, and valves in food processing and beverage lines. Pharmaceutical and Medical Applications: The corrosion resistance and ease of sterilization make these pipes suitable for use in medical equipment, surgical instruments, and pharmaceutical manufacturing. Automotive: In the automotive industry, 304/304L ERW pipes are used for exhaust systems, fuel lines, and other parts that require resistance to heat and corrosion. Chemical Processing: Their ability to resist a wide variety of chemicals makes them suitable for chemical processing equipment, reactors, and heat exchangers. HVAC Systems: Due to their strength and resistance to oxidation, they are used in heating, ventilation, and air conditioning (HVAC) systems. Marine and Offshore Applications: The pipes are used in marine environments due to their high resistance to seawater corrosion. Composition: The composition of 304 and 304L stainless steel, which are used to produce ASTM A554 ERW pipes, is as follows: 304 Stainless Steel (Typical Composition): Chromium (Cr): 18.0% - 20.0% Nickel (Ni): 8.0% - 10.5% Manganese (Mn): 2.0% max Silicon (Si): 1.0% max Carbon (C): 0.08% max Phosphorus (P): 0.045% max Sulfur (S): 0.03% max Iron (Fe): Balance 304L Stainless Steel (Typical Composition): Chromium (Cr): 18.0% - 20.0% Nickel (Ni): 8.0% - 12.0% Manganese (Mn): 2.0% max Silicon (Si): 1.0% max Carbon (C): 0.03% max (lower than 304) Phosphorus (P): 0.045% max Sulfur (S): 0.03% max Iron (Fe): Balance Key Properties: Corrosion Resistance: Both 304 and 304L offer excellent resistance to rust, corrosion, and staining in most environments, especially in food, medical, and marine applications. Weldability: 304L has a lower carbon content, which enhances its weldability and reduces the likelihood of carbide precipitation during welding. Strength: Both grades offer good tensile strength and resistance to high temperatures. Formability: 304 and 304L are highly formable and easy to manipulate into various shapes, which is useful in applications like handrails, tubes, and pipes. Conclusion: ASTM A554 304/304L ERW pipes are a high-quality choice for various industries requiring a combination of strength, corrosion resistance, and ease of fabrication. These pipes are durable, easy to weld and form, and maintain excellent performance even in harsh environments. With the corrosion resistance and aesthetic appeal of stainless steel, these pipes are invaluable in industries such as food processing, pharmaceuticals, automotive, and architecture. The key advantage of 304L over 304 is its improved weldability and reduced risk of corrosion in welded areas, making it the preferred choice in applications involving extensive welding. Overall, ASTM A554 304/304L ERW pipes offer reliable performance, longevity, and versatility, making them an excellent material choice across a broad range of applications. If you have any requirement - please email us on sales@sagarsteel.net or call us on +91 9920177883

2025-02-13T11:38:11

Keywords

- 91 9920177883

- 304 phosphorus

- formability 304

- pipes suitable

- 304l grades

- industries requiring

- pipes tanks

- improved weldability

- durable easy

- 008 max phosphorus

- heating ventilation

- wide variety

- staining makes

- good combination

- offshore applications

- medical applications

- applications requiring

- broad range

- reduced risk

- key advantage

- harsh environments

- highly formable

- carbide precipitation

- food medical

- 0045 max sulfur

- chemicals makes

- sterilization make

- aesthetic appeal

- electric current

- metal edges

- high resistance

- require resistance

- applications due

- welding strength

- strength food

- rust corrosion

- preferred choice

- highquality choice

- corrosion resistance

- versatility making

- handrails tubes

- 003 max lower

- food processing

- stainless steel

- 304l stainless steel

- strength corrosion resistance

- seawater corrosion composition

- durability corrosion resistance

- marine environments due

- corrosion chemical processing

- excellent formability common

- stainless steel family

- excellent material choice

- welded areas making

- lower carbon content

- structural elements handrails

- maintain excellent performance

- pharmaceutical manufacturing automotive

- beverage lines pharmaceutical

Submit Your Enquiry