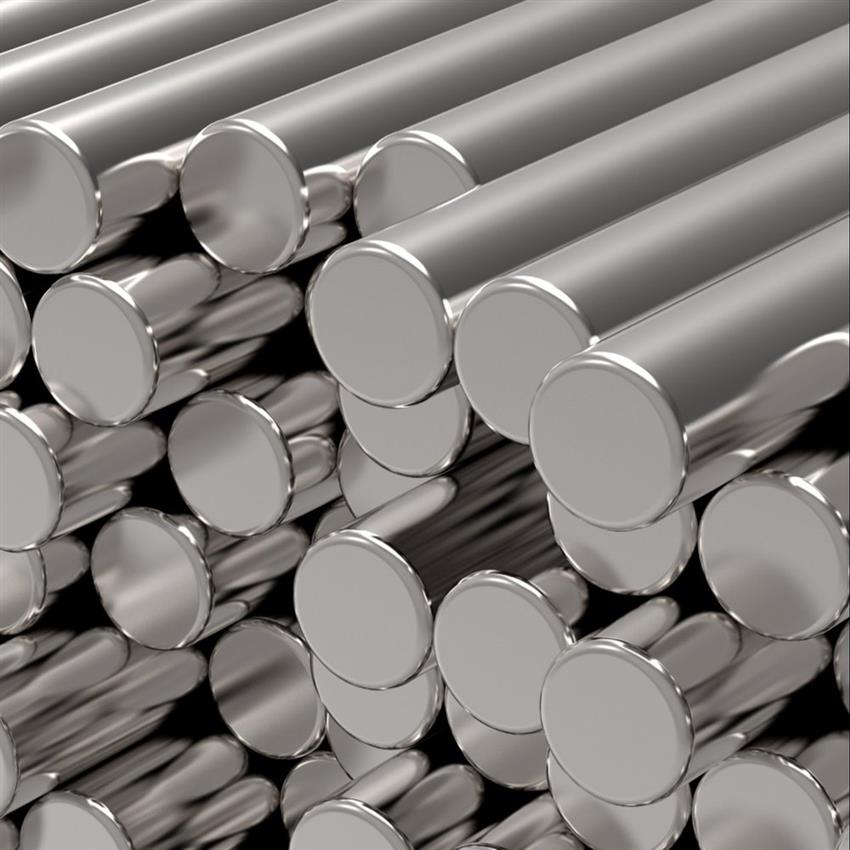

Alloy 20 Round Bars Introduction: Alloy 20 round bars are a high-performance material widely used in industries that require excellent corrosion resistance, particularly in harsh environments. This nickel-chromium-molybdenum alloy is designed to offer exceptional protection against sulfuric acid, phosphoric acid, and other aggressive chemicals. The round bars are often used in manufacturing, processing, and other industrial applications where materials must withstand high-stress, high-temperature, and corrosive environments. Composition: The composition of Alloy 20 round bars typically includes the following key elements: Nickel (Ni): 32–38% – The primary element, providing high resistance to corrosion, especially in acidic environments. Chromium (Cr): 19–21% – Enhances oxidation and corrosion resistance, particularly in acidic media. Molybdenum (Mo): 2.0–3.0% – Provides resistance to pitting and crevice corrosion. Iron (Fe): Balance – Acts as the base material and strengthens the alloy. Copper (Cu): 3.0–4.0% – Improves resistance to sulfuric acid and enhances the overall corrosion resistance. Carbon (C): ≤ 0.05% – Keeps the material stable at high temperatures and prevents carbide precipitation. Manganese (Mn): 1.0–2.0% – Adds strength and aids in the alloy’s resistance to oxidation. Silicon (Si): 0.5% – Improves high-temperature oxidation resistance. Uses: Alloy 20 round bars are used in a variety of industries, such as: Chemical Processing: Due to its corrosion resistance, especially against sulfuric and phosphoric acids, it is commonly used in chemical reactors, heat exchangers, and other equipment involved in aggressive chemical processes. Pharmaceuticals: Alloy 20 round bars are used in pharmaceutical equipment, reactors, and storage vessels because of their non-reactive nature. Food Processing: This material is safe and resistant to corrosion in food and beverage production, especially when handling acidic substances. Aerospace: In aerospace components, these round bars are used in parts that experience high stress and corrosion resistance. Power Generation: Components in power plants, such as turbines and reactors, also benefit from the high durability and strength of Alloy 20 round bars. Marine Engineering: Alloy 20’s resistance to chloride stress corrosion makes it suitable for marine applications where saltwater can cause corrosion. Oil & Gas: This alloy’s properties make it a popular choice for critical components in the oil and gas industry, particularly in sour gas applications. Conclusion: Alloy 20 round bars are a versatile and durable material, offering exceptional corrosion resistance, especially in aggressive environments such as those encountered in chemical, food processing, and pharmaceutical industries. With its unique combination of nickel, chromium, and molybdenum, Alloy 20 provides the ideal solution for applications demanding resistance to a wide range of acidic and corrosive conditions. Its strength, durability, and versatility make it indispensable in industries ranging from aerospace to marine engineering. Whether for structural components, pipes, or valves, Alloy 20 continues to be a preferred choice for ensuring long-lasting performance in challenging environments. If you have any requirement - please email us on sales@sagarsteel.net or call us on +91 9920177883

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

2025-02-12T11:27:33

Alloy 20 Round Bars Introduction: Alloy 20 round bars are a high-performance material widely used in industries that require excellent corrosion resistance, particularly in harsh environments. This nickel-chromium-molybdenum alloy is designed to offer exceptional protection against sulfuric acid, phosphoric acid, and other aggressive chemicals. The round bars are often used in manufacturing, processing, and other industrial applications where materials must withstand high-stress, high-temperature, and corrosive environments. Composition: The composition of Alloy 20 round bars typically includes the following key elements: Nickel (Ni): 32–38% – The primary element, providing high resistance to corrosion, especially in acidic environments. Chromium (Cr): 19–21% – Enhances oxidation and corrosion resistance, particularly in acidic media. Molybdenum (Mo): 2.0–3.0% – Provides resistance to pitting and crevice corrosion. Iron (Fe): Balance – Acts as the base material and strengthens the alloy. Copper (Cu): 3.0–4.0% – Improves resistance to sulfuric acid and enhances the overall corrosion resistance. Carbon (C): ≤ 0.05% – Keeps the material stable at high temperatures and prevents carbide precipitation. Manganese (Mn): 1.0–2.0% – Adds strength and aids in the alloy’s resistance to oxidation. Silicon (Si): 0.5% – Improves high-temperature oxidation resistance. Uses: Alloy 20 round bars are used in a variety of industries, such as: Chemical Processing: Due to its corrosion resistance, especially against sulfuric and phosphoric acids, it is commonly used in chemical reactors, heat exchangers, and other equipment involved in aggressive chemical processes. Pharmaceuticals: Alloy 20 round bars are used in pharmaceutical equipment, reactors, and storage vessels because of their non-reactive nature. Food Processing: This material is safe and resistant to corrosion in food and beverage production, especially when handling acidic substances. Aerospace: In aerospace components, these round bars are used in parts that experience high stress and corrosion resistance. Power Generation: Components in power plants, such as turbines and reactors, also benefit from the high durability and strength of Alloy 20 round bars. Marine Engineering: Alloy 20’s resistance to chloride stress corrosion makes it suitable for marine applications where saltwater can cause corrosion. Oil & Gas: This alloy’s properties make it a popular choice for critical components in the oil and gas industry, particularly in sour gas applications. Conclusion: Alloy 20 round bars are a versatile and durable material, offering exceptional corrosion resistance, especially in aggressive environments such as those encountered in chemical, food processing, and pharmaceutical industries. With its unique combination of nickel, chromium, and molybdenum, Alloy 20 provides the ideal solution for applications demanding resistance to a wide range of acidic and corrosive conditions. Its strength, durability, and versatility make it indispensable in industries ranging from aerospace to marine engineering. Whether for structural components, pipes, or valves, Alloy 20 continues to be a preferred choice for ensuring long-lasting performance in challenging environments. If you have any requirement - please email us on sales@sagarsteel.net or call us on +91 9920177883

2025-02-12T11:27:33

Keywords

- 91 9920177883

- industries ranging

- strength durability

- sulfuric acid

- aerospace components

- preferred choice

- marine engineering

- wide range

- ideal solution

- molybdenum alloy 20

- nickel chromium

- unique combination

- pharmaceutical industries

- popular choice

- power plants

- beverage production

- storage vessels

- phosphoric acids

- material stable

- base material

- round bars

- aggressive chemicals

- nickelchromiummolybdenum alloy

- corrosion resistance

- challenging environments

- aggressive environments

- harsh environments

- critical components

- marine applications

- high durability

- high temperatures

- industrial applications

- versatility make

- corrosive conditions

- gas industry

- equipment involved

- alloys resistance

- manufacturing processing

- corrosion oil gas

- corrosive environments composition

- pharmaceutical equipment reactors

- corrosion resistance carbon

- applications demanding resistance

- chemical food processing

- alloys properties make

- highperformance material widely

- structural components pipes

- experience high stress

- chemical processing due

- ensuring longlasting performance

- withstand highstress hightemperature

- offer exceptional protection

Submit Your Enquiry